Neue Website | 18.05.2024

Unsere neue Website ist online! Im Bereich "News" wollen wir kontinuierlich über die Entwicklung der KT Kunststofftechnik berichten. Die Neuheiten der vergangen zwei Jahre finden Sie als Archivbeiträge direkt unter diesem Beitrag.

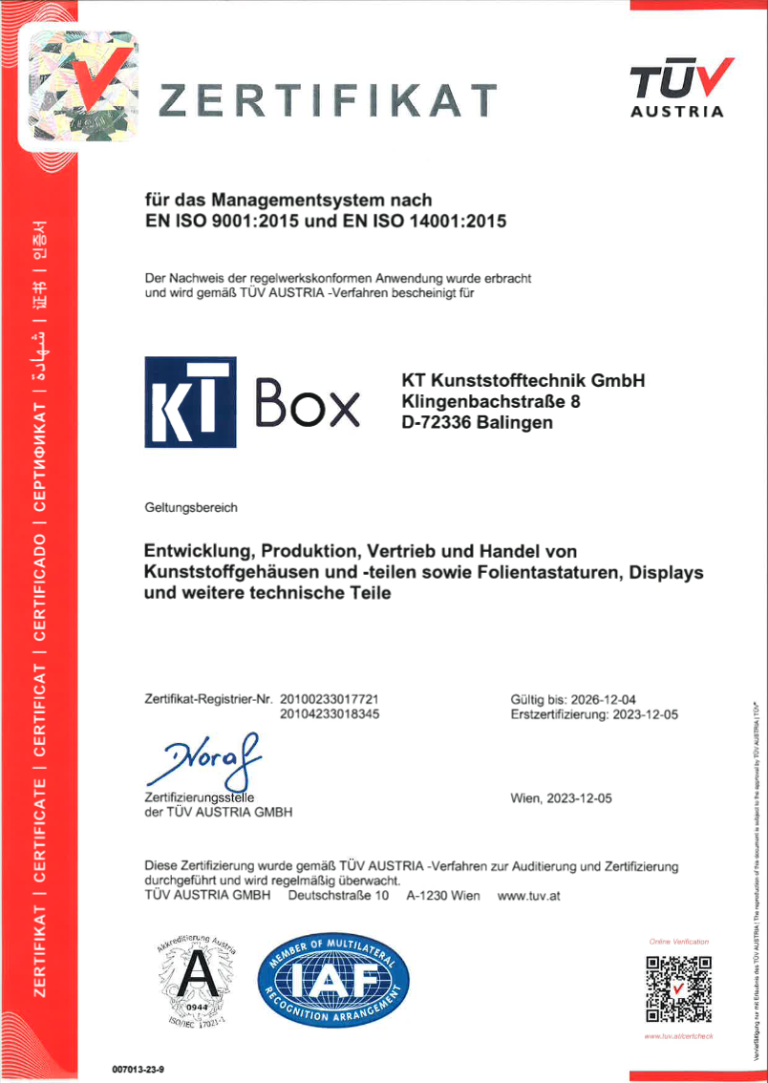

ISO 9001 und 14001 Zertifikat | 05.12.2023

Unser neues ISO 9001 Zertifikat, ausgestellt von TÜV Austria.

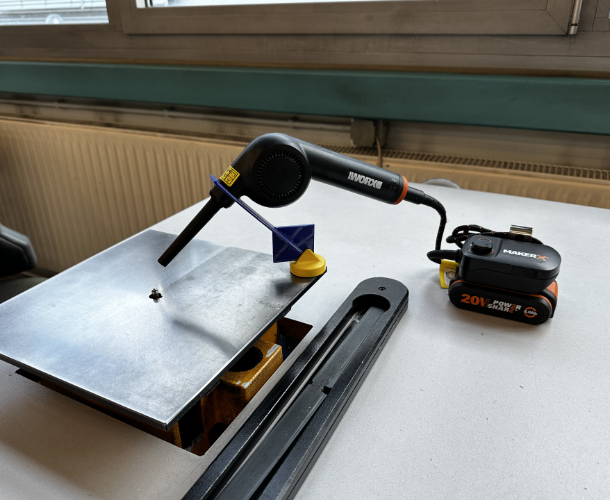

Druckluft | 09.02.2023

Wir reduzieren den Einsatz von Druckluft. Um Energie einzusparen, setzt die KT-Kunststofftechnik auf kleine Gebläse welche die energieaufwendige Druckluft ersetzten.

Transport | 04.02.2023

Die KT-Kunststofftechnik setzt in Zukunft einen Elektrotransporter ein, um Kleintransporte umweltfreundlicher zu machen.

Social Media | 17.01.2023

Unsere Eigenmarke KT Box ist jetzt auch auf Instagram zu finden. Unter @ktbox.official sind verschiedenste Eindrücke unserer Produkte zu sehen.

KT-BOX DIE EIGENMARKE DER KT KUNSTSTOFFTECHNIK | 20.09.2022

Wir produzieren und vertreiben nachhaltige Produkte aus Kunststoff. Alle Produkte sind langlebig und zu 100% wiederverwertbar. Bei der Herstellung werden vorzugsweise recycelte Kunststoffe verwendet. Die Entwicklung und die Produktion erfolgen vollständig in der Schweiz und in Deutschland.

Unsere einzigartigen Allwettermöbel können sowohl im Außen-, als auch im Innenbereich eingesetzt werden. Als Gartenmöbel eingesetzt überstehen sie jedes Wetter und nach einem Regensturm oder einer Ladung Saharastaub können sie einfach und problemlos gereinigt werden. Die schwarzen Möbel sind aus recyceltem Kunststoff hergestellt, nur für die poppigen farbigen Ausführen verwenden wir Neuware.

Die Allwettermöbel bieten wir in mehreren Designlinien an, die sowohl im Trend als auch zeitlos sind.

Elektro-Betrieb | 18.03.2022

Die Firmenfahrzeuge der KT Kunststofftechnik in Balingen und in der Schweiz werden nun ausschließlich elektrisch betrieben.

KT Kunststofftechnik Schweiz GmbH | 04.01.2022

Seit Januar 2022 werden unsere Schweizer Kunden von der KT Kunststofftechnik Schweiz GmbH betreut und beliefert. Wir sind somit dichter bei unseren Kunden und wir übernehmen sämtliche Aus- und Einfuhraktivitäten.

Erste Hybridgehäuse | 15.10.2021

Die KT Kunststofftechnik entwickelt die ersten Hybridgehäuse, die sowohl mit der Fräs-, Biege- Schweisstechnik (FBS-Technik), als auch im Spritzguss hergestellt werden können. Dabei werden die Gehäuse so gestaltet, dass mit der FBS Technik eine sehr schnelle Marktreife mit niedrigen Intitialkosten erreicht wird. Bei steigendem Absatzvolumen können später einzelne Teile oder auch das gesamte Gehäuse in der Spritzgusstechnik hergestellt werden, die bei sehr grossen Stückzahlen kostengünstiger ist.

EMBRAER PORTUGAL | 01.09.2021

EMBRAER PORTUGAL Estrutura em Compósitos listet die KT Kunststofftechnik als Lieferant.

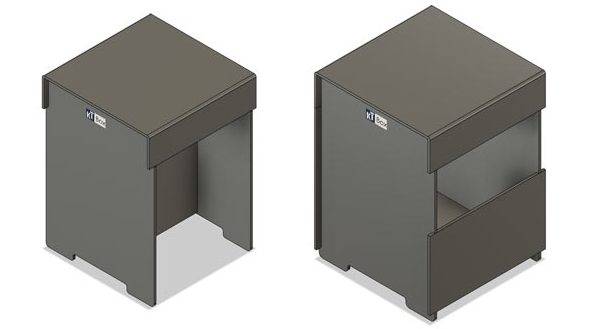

KT Box | 01.11.2020

Mit unsere neuen Eigenmarke KT Box bieten wir vielfältig nutzbare Kunststoffgehäuse an, die ab Stückzahl 1 in unserem Shop bestellt werden können. Gestartet haben wir mit Gehäusen für Raspberry PI und ein neu entwickelter Schiebeschnappverschluss ermöglicht die Montage mit einem Handgriff. Weitere Produkte werden folgen.

© 2024 KT Kunststofftechnik GmbH. Alle Rechte vorbehalten.

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.